GWX Series

Grease Recovery and Refining

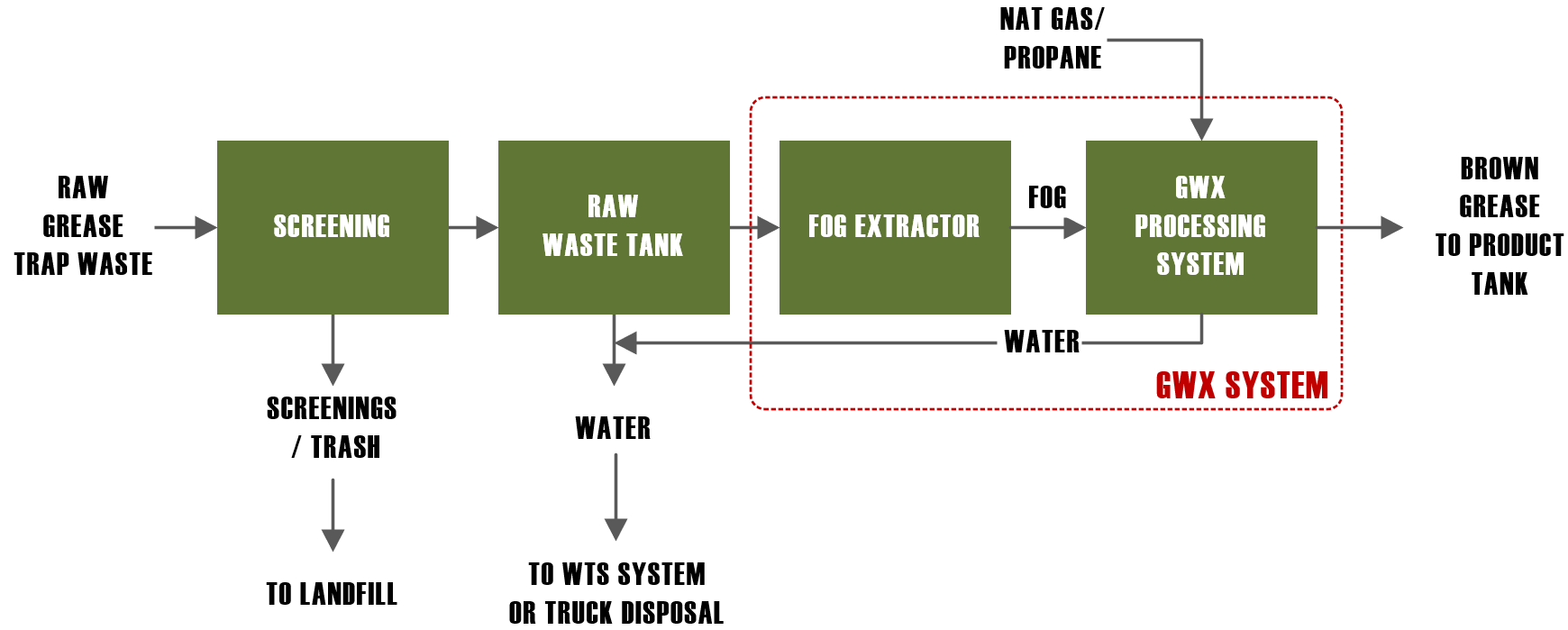

The GWX is a revolutionary way of recovering marketable brown grease from grease trap waste. The automated system combines extraction, rendering and decanting functions into a single unit, significantly reducing cost, footprint, and labor while separating valuable grease from a wide variety of receiving equipment.

How it Works

The GWX unit is installed adjacent to the customer provided raw waste holding tank. The flexible GWX FOG extractor is installed through the top of the holding tank. The operator initiates the run cycle and the GWX control system takes over. The extractor is run, selectively extracting the FOG that floats in the raw waste tank. The FOG then drops by gravity into the processing tank where it is carefully heated by the on-board thermal rendering system. The recovered FOG separates into brown grease, settled solids and water. The water is transferred back to the raw waste holding tank automatically by the GWX control system, maximizing throughput and minimizing heat input. Once the rendering process is complete, the operator transfers the finished brown grease through a final filter and the process is re-started.

SYSTEM SPECS

GWX-500 – up to 10,000 gal/day grease trap waste

GWX-1000 – up to 20,000 gal/day grease trap waste

Designed to work with any type of raw waste tank (Underground vault, EQ basins, frac tanks, poly tanks, etc..)

Stainless steel product contact surfaces for long service life

Fully automated filling and processing

Industry leading thermal efficiency by only processing FOG fraction

Fully skid mounted with single point power and fuel connections

Operates on Propane or natural gas (fuel oil optional)

Single phase 240V OR three phase 230/460V electrical options

ADVANTAGES

Works with any type of raw waste tank

Small footprint (5’Wx10′ L)

No wasted energy heating water

No manual transfers

No complicated skimmer mechanisms

No complicated boiler fuel system

Maximum grease recovery

Custom units for higher capacity available