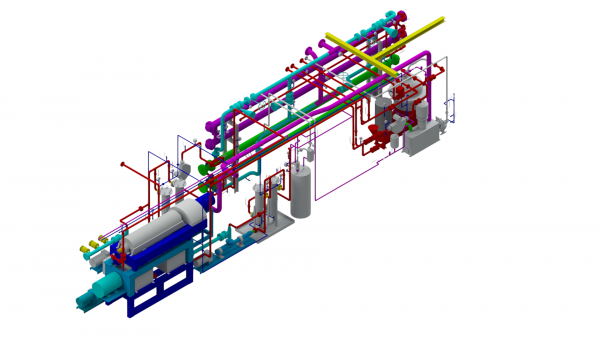

Centrifuge Refining Systems (CRS)

When maximum efficiency and high throughput are goals, the CRS series of centrifuge refining systems are the perfect solution. Whether you are trying to maximize recovery of oils and grease from difficult to handle feedstock, or to squeeze residual waste streams to produce higher yields and reduce disposal costs, the custom built CRS series provides a highly versatile solution. Perfected over a decade of work, our design approach utilizes remanufactured centrifuges for lower cost, shorter lead time, and US based parts and support.

How it Works

The CRS systems can process a wide variety of feed, either solid or liquid. For streams like grease trap waste sludge or used cooking oil sludge, the process begins with preheating the feed in a customer provided feed tank. The feed is then sent through a coarse filtration process to remove oversize solids that could damage downstream equipment. The feed then enters a continuous decanter centrifuge where it is subjected to forces of 3000G to remove 95% of solids and grit. The clarified feed is then put through a fine filter before being sent to an automatic high speed separator centrifuge to separate the recoverable oil, water and fines. This two stage system allows for maximum oil recovery, feed flexibility and the highest oil quality.

Feed Streams

• DAF sludge

• Clarifier float

• Basin skimmings

• Meat and bone scrap

• Used Cooking Oil

• Grease Trap Waste

• Food plant waste

• Expired food / oils

Products

• Yellow grease (<2% MIU)

• Brown grease (<2% MIU)

• Tallow (<2% MIU)

Benefits

• Maximum yield of FOG from any feedstock

• Wide range of possible feedstock

• Highest quality finished oil on the market

• Utilizes high quality re-manufactured centrifuges

• U.S. parts availability

• U.S. based support

Features

• Full PLC process controls

• Skid mounted for quick deployment

• Can be set up on trailer to be fully portable

• Multiple stages of size reduction, cooking, filtration and separation available

• All stainless steel product contact

• Multiple heating methods (hot water, steam, thermal oil) available

• Can incorporate additional processing stages for metals reduction